Mustafa Kürşat Yalçın

5 Min Read

Manufacturing smarter, not wasteful — let’s explore how data analytics is closing loops and opening doors to sustainability!

Introduction

In traditional manufacturing, waste has long been treated as an inevitable byproduct of production — scraps on the factory floor, excess energy consumption, or discarded packaging. But what if we could flip the script? What if waste wasn’t just something to be discarded but an opportunity for efficiency, cost savings, and innovation?

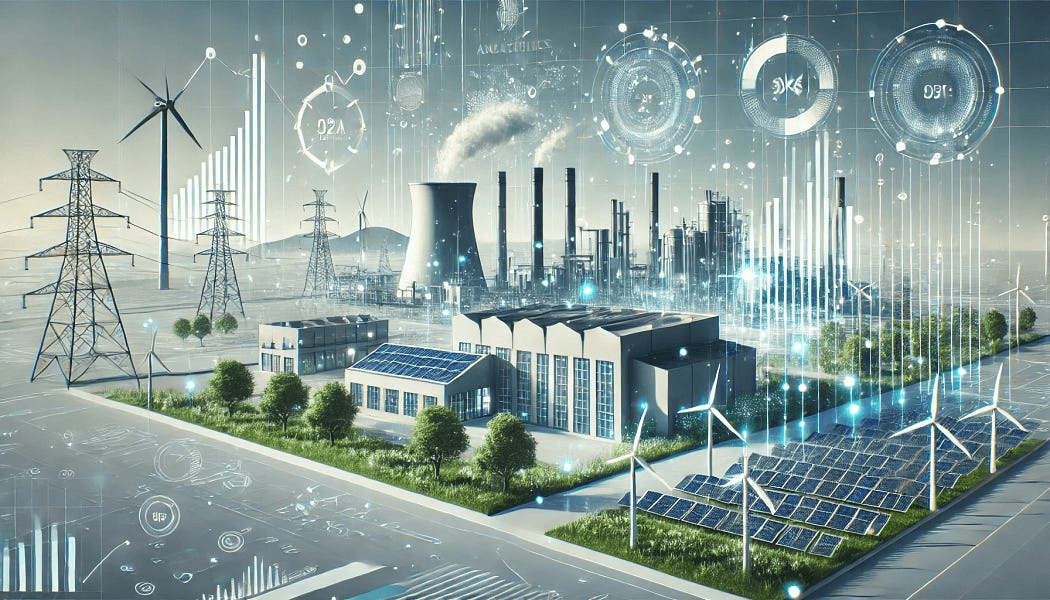

Enter the concept of the circular data economy: a model that leverages data analytics to reduce waste, extend the lifecycle of materials, and create smarter, more sustainable manufacturing processes. By combining cutting-edge technologies like IoT sensors, AI, and advanced analytics, manufacturers are turning waste streams into valuable resources and designing processes that maximize efficiency while minimizing environmental impact.

In this blog, we’ll explore;

how circular data economies are transforming manufacturing,

the role of data analytics in waste reduction,

real-world examples of success,

and what lies ahead in this data-driven revolution.

Let’s dive in!

What Is a Circular Data Economy?

A circular economy aims to move away from the “take, make, dispose” model of manufacturing. Instead, it focuses on designing processes that keep materials in circulation for as long as possible, minimizing waste and maximizing resource efficiency.

Now, add data analytics to the mix, and you get the circular data economy. This approach uses real-time data and advanced analytics to create feedback loops that help manufacturers monitor, adjust, and improve every aspect of production.

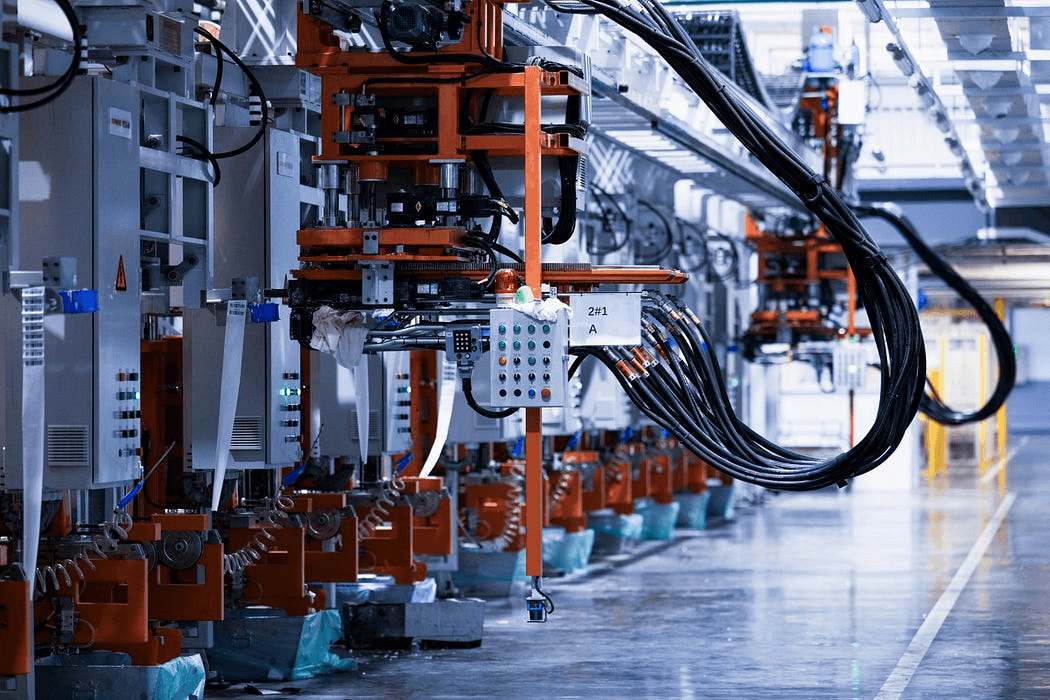

How does this work in practice? Imagine a manufacturing facility equipped with IoT sensors that monitor energy consumption, track raw material use, and identify inefficiencies in production lines. Data collected from these sensors is fed into an AI-driven platform, which provides actionable insights to:

Reduce material waste during production.

Optimize energy usage.

Identify opportunities to recycle or repurpose byproducts.

It’s all about creating a system that’s smarter, leaner, and more sustainable.

How Data Analytics Drives Circular Economies

Data analytics is the backbone of the circular economy in manufacturing. Here’s how it transforms waste management and production efficiency:

1. Real-Time Monitoring of Resource Usage

IoT sensors placed throughout production facilities collect real-time data on raw material use, energy consumption, and waste generation. This allows manufacturers to track inefficiencies the moment they arise. For instance, a factory might identify that a machine is consuming 10% more energy than usual, signaling the need for maintenance. Fixing this not only saves energy but also extends the lifespan of equipment, reducing long-term waste.

2. Predictive Maintenance Reducing Waste

Predictive maintenance isn’t just about avoiding machine downtime — it’s also about minimizing waste caused by faulty equipment. Data analytics can predict when a machine is likely to fail, allowing manufacturers to repair it before it causes defective products or consumes excess energy.

General Electric (GE) is a leader in this space. By implementing predictive maintenance across their production lines, GE has reduced machine downtime by 30% and decreased waste from defective parts.

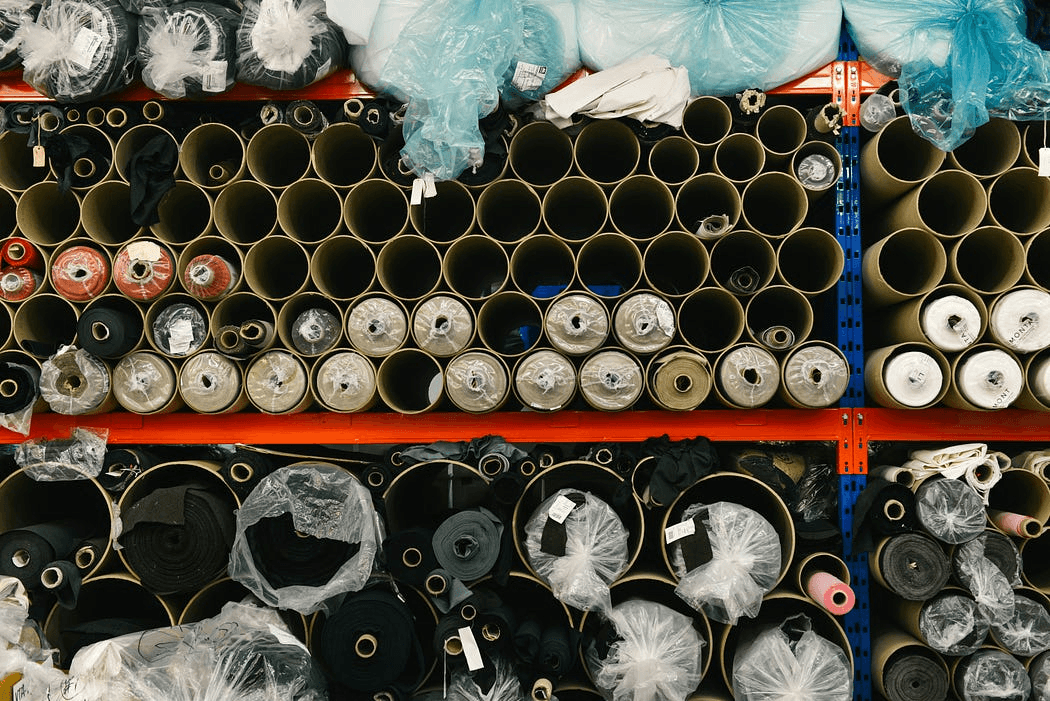

3. Optimizing Material Flows

Advanced analytics can identify how raw materials flow through production, highlighting where resources are being overused or underutilized. This insight helps manufacturers redesign workflows to be more efficient.

Take Unilever, for example. Using analytics to optimize its material flows, the company reduced food waste in production by 50%, transforming surplus ingredients into new products or donating them for use elsewhere.

Benefits of Circular Data Economies

Implementing a circular data economy isn’t just good for the planet — it’s good for business. Here are the key benefits:

Cost Reduction: Minimizing waste and optimizing resource use saves money at every step.

Operational Efficiency: Real-time analytics ensures processes run smoothly with minimal downtime.

Regulatory Compliance: Meeting sustainability targets helps businesses avoid penalties and maintain a competitive edge.

Enhanced Brand Reputation: Consumers increasingly prefer brands committed to sustainability. Circular economies position companies as leaders in environmental responsibility.

Real-World Success Story: McKinsey’s Work with a Global Automotive Manufacturer

Background

A global automotive manufacturer approached McKinsey & Company with a pressing challenge: rising waste levels in their production processes drove up costs and increased environmental scrutiny. The company wanted to integrate a circular economy approach but lacked the data infrastructure to do so effectively.

Challenge

The manufacturer’s production lines were generating excessive material waste and energy inefficiencies. Scrap rates were high, and waste streams were not being reused effectively. The company struggled to identify where the problems were occurring or how to tackle them systemically.

Solution

McKinsey introduced a data-driven circular economy strategy, implementing IoT sensors and advanced analytics across the manufacturer’s facilities. The approach involved:

Real-Time Monitoring: IoT sensors tracked material usage, energy consumption, and waste generation at every production stage.

Analytics Dashboards: A centralized dashboard provided insights into inefficiencies, highlighting areas for improvement.

Recycling Programs: McKinsey designed workflows to capture and repurpose waste materials, reintroducing them into the supply chain.

Impact

35% Reduction in Material Waste: Enhanced monitoring and analytics allowed the company to reclaim and reuse excess materials.

Improved Sustainability Metrics: The company gained a competitive edge by meeting global sustainability standards and reducing environmental impact.

Conclusion

Circular data economies are redefining manufacturing by proving that waste isn’t the end of the story — it’s the beginning of smarter, more efficient processes. From IoT sensors monitoring every detail to AI predicting maintenance needs, the integration of data analytics allows manufacturers to eliminate inefficiencies, cut costs, and repurpose materials that would otherwise be discarded.

By adopting closed-loop recycling systems, optimizing resource flows, and building resilience against supply chain disruptions, manufacturers are not just solving today’s problems — they’re preparing for tomorrow’s challenges. Predictive maintenance, real-time monitoring, and smarter workflows make it possible to save millions, minimize environmental impact, and meet increasingly strict sustainability regulations.

The future of manufacturing is circular, data-driven, and brighter than ever. It’s time to stop treating waste as an unavoidable expense and start treating it as an opportunity for innovation!

Ready to take the leap?